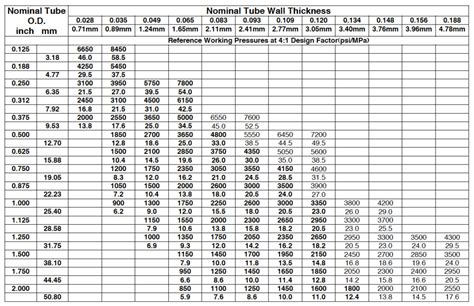

tubing wall thickness measurement|steel tubing wall thickness chart : Big box store Tubing is measured by three main dimensions, except for the length. The three charts below are listed by these three dimensions: the outside diameter (O.D.), the wall thickness (W.T.), and the inside diameter (I.D.), which is specified in .

Super hot scene. 18.3k 80% 15min - 360p. Na. 13.5k 81% 1min 28sec - 360p. (2016 july) super hot cam girls-1. 6.5k 80% 1min 14sec - 360p. (2016 july) super hot cam girls-32. .

{plog:ftitle_list}

Resultado da Cibelly Ferreira (Professora de inglês) SimpCity Instagram. Follow Discuss. 972 Media. 29 Likes.

The wall thickness (WT) of tubing can also be measured by the standard gauge from 0 (heaviest) to 24 (lightest) which correspond to a range of wall thicknesses. This chart includes outside diameter, inside diameter, wall thickness, and gauge.For manual thickness measurements, the 39DL PLUS™ gauge and 45MG gauge with Single .Use the rounded anvil to measure the wall thickness of curved surfaces, such as pipe and .In order to perform Wall Thickness Measurements, including pitting (external or internal .

Designed with a rounded jaw for measuring the wall thickness of pipe, tubing, and other .

Tubing is measured by three main dimensions, except for the length. The three charts below are listed by these three dimensions: the outside diameter (O.D.), the wall thickness (W.T.), and the inside diameter (I.D.), which is specified in .that is made against nominal values (not allowable pipe wall thickness values) do not provide an accurate measurement of remaining pipe wall thickness. ASTM specifications for seamless pipe manufacturing standards permit a 12.5% under-tolerance on new pipe wall thickness. As an example, a Schedule 40, 3-inch pipe nozzle has a

pendulum impact test procedure

PosiTector UTG Ultrasonic Wall Thickness Gauges measure the remaining wall thickness of materials such as steel, plastic and more using ultrasonic technology. Ideal for measuring the effects of corrosion or erosion on tanks, .

For tube, hose, and small diameter pipe, the BenchLinc™ ID-OD-Wall system provides for automatic rotation of the sample to measure total wall thickness from multiple angles. VIEW PRODUCT Flaw DetectionPlastic pipe: Both in-line and off-line measurement of plastic pipe wall thickness can be performed to ensure concentricity. Plastic tubing: Small tubing with diameters as small as 2 mm or 0.080 in., including catheters and other including medical tubing, can be measured with focused transducers.Efficient Wall Thickness Measurement with Ultrasonic Testing. In order to make the most out of your wall thickness measurement testing, you need the right ultrasonic testing equipment: a full suite of scanners, instrumentation, software, and auxiliary tools that can get the job done right.

An inline wall thickness measurement system at the output end of a forming mill in a seamless steel tube production line is illustrated in Figure 2. It has a measurement head that contains beam delivery optics for the pulsed ultrasonic-generating laser, together with sensor optics for the remote, fiber-coupled CW laser ultrasonic receiver.

7.2.6 Determine the minimum remaining wall thickness measurement for each grading unit. 7.2.7 The minimum remaining wall thickness for each Grading Unit shall be recorded on the API Thickness Measurement Report Form. 7.2.8 Determine the Grading Unit Flaw Category for each grading unit. See figure 2 for a list of Grading Unit Flaw Categories. For measuring the wall thickness of the pipe, two metal spheres with diameters of 6.3 mm were placed on either side of the pipe during the radiography exposure. The algorithms were processed with the same parameters and repeated for the pipe radiography images. The results show that the details are more apparent in the output images than they .Our gauges are used all over the world for thickness measurement of storage tanks, pipe wall, cast iron parts, plastics, alloys and more. Have a special application? . Measure cylinder wall thickness, deck height, chassis tubing & more. View Category. ZX-1. Manually adjust velocity to calibrate to any material type. Resolution:.001" (0.01 mm)A reversible anvil lets you adapt the gauge to the shape of the object you are measuring. Use the round face on the anvil to measure the wall thickness of pipe, tubing, and other curved surfaces. Use the flat face to measure sheet metal, paper, and other flat stock.

In this paper, The coiled tubing wall thickness evaluation system is proposed based on the pulsed alternating current field measurement technique. The coiled tubing wall thickness evaluation model .The Wall Thickness of the tubing is measured in inches (in.) or millimeters (mm). Refer to the tubing’s Technical Data to determine the thickness of the wall. 4.

According to this assumption, if the pipe’s wall thickness is 3mm, then one would need to penetrate 6mm of steel to achieve accurate measurements. This assumption is incorrect. When dealing with the outer wall, the thickness of steel requiring penetration is nearly zero. In the case of the pipe’s inner wall, the opposite is the case. Jin et al. proposed a tubing wall-thickness measurement method based on a measurement sensor and designed an online tubing wall-thickness measurement system with a wall-thickness measurement accuracy of ±0.05 mm. The indirect measurement method is mainly based on the principle of eddy current measurement and ultrasonic measurement, .The probe acquires the thickness of the advancing thin tubing as a long profile – at up to 100,000 points (A-scans) per second; Each A-scan delivers optical thickness of the upper wall, the enclosed air space, and the lower wall; .Pipe sizes, inside and outside diameters, wall thickness, schedules, weight and weight of pipe filled with water - Metric Units. ASTM D1785 and ASTM F441 - PVC and CPVC Pipes Schedule 40 & 80 Standard dimensions and weight of PVC - Polyvinyl Chloride - and CPVC - Chlorinated Polyvinyl Chloride.

Pipe wall thickness calculation is one of the important basic activities for every piping engineer. Process plants deal with the fluids that flow inside the pipe at high pressure and temperature.So, the pipe deals with high circumferential pressure which can cause the bursting of the pipe if the pipe schedule or thickness is not enough. Hence, The designers need to find . A pipe's wall thickness measurement is crucial for quality assurance and safety purposes. The size, composition, and location of the pipe are only a few of the variables that affect the thickness measurement technique. Ultrasonic thickness measurement, magnetic particle inspection, radiographic testing, and optical profiling are some of the . An inadequate wall thickness can lead to catastrophic failures, leaks, and potentially hazardous situations. To ensure the safety and efficiency of any pipe system, it is crucial to have an accurate measurement of its wall thickness. Understanding Wall Thickness Gauges. Ultrasonic gauges are widely used for non-destructive testing of pipe walls.

pendulum impact test rig

Wall Thickness; Measured in millimeters, wall thickness can vary depending on the tubing’s material and application. Common metric wall thicknesses range from 0.5 mm to 50 mm. A thicker wall provides higher pressure resistance and mechanical strength, while a thinner wall offers reduced weight and cost. How To Measure Metric Tubing?

Measuring the wall thickness and roundness of tubing glass. Glass tubes are used in medical industry for the production of vials, ampoules and syringes. The wall thickness has to be controlled very precisely, in view of the strict quality control and regulations in medical industry.

The initial value of the temperature during the simulation is set to 300 K. The laser spot radius is 0.5 mm, the pulse rise time is 8 ns, the power density is 1 × 10 12 W/m 2, and the material light absorption coefficient is 0.37.The selected calculation time step is 1 × 10 −9 s, and the maximum mesh size is 2 × 10 −5 m, which is less than 1/10 of the ultrasonic length.Our passion for quality and system security drives LAP to be a world-leading manufacturer of tube measurement systems. With our non-contact laser measurement systems, you are able to guarantee the required product quality of your tubes regardless of the kind of production process.In recent years, with the exploitation of shale gas, the amount of coiled tubing has increased dramatically. Due to the harsh working environment, the wall thickness of the coiled tubing is easily thinned. In this paper, The coiled tubing wall thickness evaluation system is proposed based on the pulsed alternating current field measurement technique. The coiled tubing .

pendulum impact test systems

All you need to do is turn it on, be sure it's closed, hit the "zero" button and then open them to measure the OD and wall thickness of the pipe you are going to use. Find OD listed in the 1st column and thickness in the 3rd and then you'll find the classification for your pipe in the blue panel that corresponds to the OD and Wall Thickness you .Wall thickness measurement for hot seamless tube and pipe mills Tecnar has over 20 years of experience implementing non-contact ultrasonic thickness gauges in hot seamless tube mills. The Lut 2.0 is engineered to provide the most accurate wall thickness information in a robust, low-maintenance package. Talk to an expertSquare Tubing Continued on next page Mechanical Tubing: Under 2" or 11 ga and under - ASTM A-513. Structural Tubing: 2" and over 11 ga wall thickness - ASTM A-500 Grade B. Standard Lengths: 20 ft., 24 ft., 40 ft., and 48 ft. Wall Thickness (inches) Weight (lbs./ft.) Outside Dimension & Gauge (inches) Wall Thickness (inches) Weight (lbs./ft .

tubing wall thickness pressure chart

Resultado da CEAD / UNIFAL - Universidade Federal de Alfenas Rua Gabriel Monteiro da Silva, 700 . Alfenas/MG . CEP 37130-000 Fone: (35) 3701-9282 . Fax: (35) 3701-9280 Informe à Comunidade UNIFAL-MG Com o objetivo de melhorar e ampliar os recursos oferecidos no nosso Ambiente Virtual de .

tubing wall thickness measurement|steel tubing wall thickness chart